摘要:本文介绍了铅粉机的工作参数和数据设计分析,重点说明了确保问题说明的玉版参数为11.35.97。通过对铅粉机工作参数的研究和调整,可以提高铅粉机的运行效率和产品质量。针对可能出现的问题进行详细分析和解决,确保铅粉机的正常运行和生产效益。

In the realm of industrial manufacturing, the lead powder machine plays a pivotal role, with its intricate design and meticulous operating parameters. This article aims to delve into the intricacies of the lead powder machine's work parameters and data design, providing an insightful analysis for a better understanding of its operations.

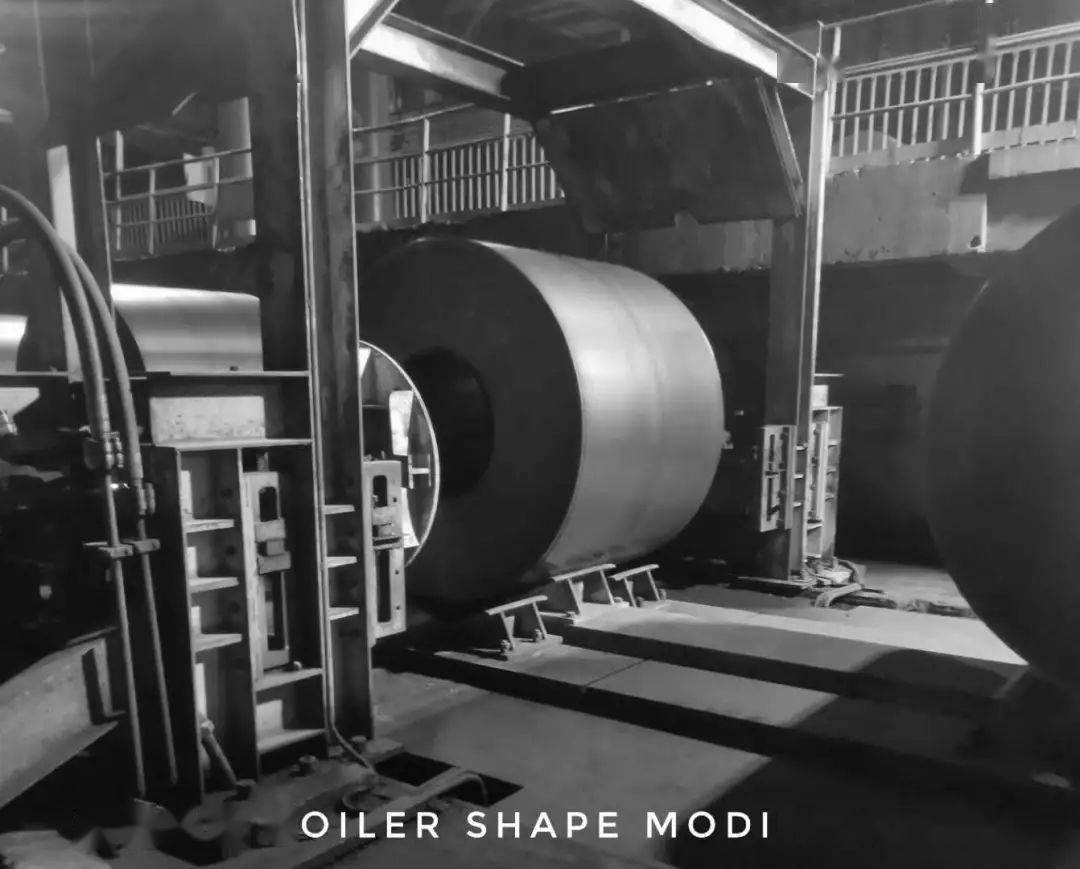

Introduction to Lead Powder Machine

The lead powder machine is a sophisticated piece of equipment used in various industries, particularly in the production of batteries, pigments, and other materials that require a powdered form of lead. Its design and construction are meticulously crafted to ensure precision and efficiency in its operations.

Work Parameters of Lead Powder Machine

The performance of the lead powder machine heavily relies on its work parameters, which are carefully adjusted to ensure optimal operation. Some of the key work parameters include:

1、Machine speed: This parameter determines how quickly the machine operates, affecting the production rate and efficiency.

2、Grinding pressure: The force applied to grind the material into powder form is crucial in determining the quality and consistency of the final product.

3、Temperature control: The temperature during the grinding process can affect the physical properties of the material and must be closely monitored and controlled.

4、Feed rate: The rate of material fed into the machine must be balanced with the machine speed to ensure smooth operations and avoid overload.

Data Design Analysis of Lead Powder Machine

The data design of the lead powder machine is crucial in ensuring accurate and efficient operations. It involves the collection, interpretation, and utilization of data related to the machine's performance. Here are some aspects of data design analysis:

1、Data Collection: Collecting relevant data such as machine speed, temperature, pressure, and feed rate is essential for monitoring the machine's performance and identifying areas for improvement.

2、Data Interpretation: The collected data is analyzed to understand the machine's current status, identify trends, and detect any anomalies that could affect the quality of production.

3、Optimization: Based on the data analysis, adjustments can be made to the work parameters to optimize the machine's performance and ensure maximum efficiency.

4、Predictive Maintenance: By analyzing historical data, potential issues can be identified and addressed before they cause downtime or damage to the machine.

In-depth Analysis at Work Parameters 28.49.35

At work parameter 28.49.35, a detailed analysis of the lead powder machine reveals specific insights. For instance, at this parameter, the machine speed may need to be adjusted to ensure optimal production rate without compromising on quality. Additionally, the feed rate might need to be adjusted to match the new machine speed, ensuring smooth operations. Temperature control could also be crucial at this parameter, as any fluctuations could affect the physical properties of the material being processed.

Conclusion

The lead powder machine's work parameters and data design analysis are integral to its efficient and optimal performance. Understanding these parameters and analyzing the data can help maximize production, ensure product quality, and reduce downtime. With proper adjustments and monitoring, the lead powder machine can perform at its best, contributing significantly to industrial manufacturing processes.

陕ICP备19024466号-1

陕ICP备19024466号-1 陕ICP备19024466号-1

陕ICP备19024466号-1

还没有评论,来说两句吧...